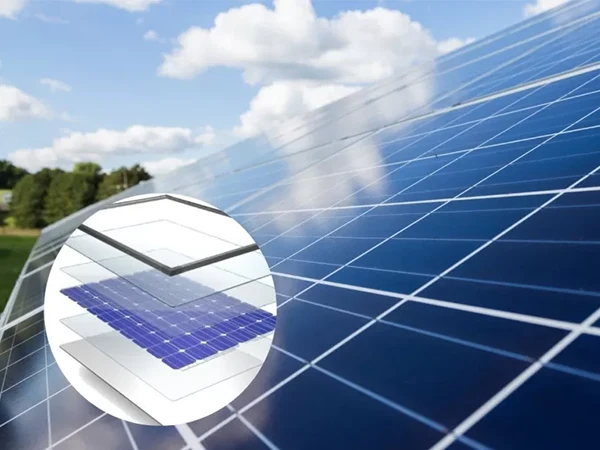

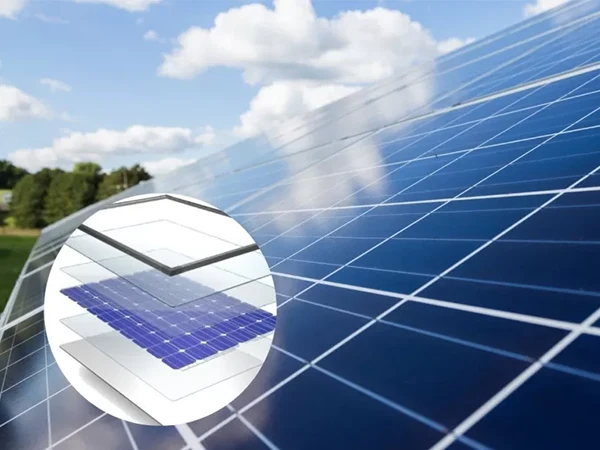

For photovoltaics industry

Glass fiber twisted fabric is a flat, multi-directional reinforced fabric woven from single or plied twisted glass fiber yarns using air-jet or rapier looms. The fabric is available in plain, twill, and satin weave structures. This product is primarily used in glass fiber prepregs, aerospace, electronics and electrical appliances, sports equipment, new energy vehicles, photovoltaics, and other advanced fields.

Our glass fiber twisted fabric undergoes stringent quality tests and offers outstanding corrosion resistance, flame retardancy, thermal insulation, durability, and stability, making it suitable for a wide range of demanding environments.

| Product Code | Weave Structure | Weight (g/m2) | Warp and Weft Density (Inch) | Yarn Specification (Tex) | Width (mm) | Thickness (mm) | ||

|---|---|---|---|---|---|---|---|---|

| Warp | Weft | Warp | Weft | |||||

| EW25P | Plain weave | 25±2 | 50 | 45 | 6.5 | 6.5 | 3300 | 0.03±0.01 |

| EW50P | Plain weave | 50±2 | 58.8 | 42.5 | 12 | 12 | 3300 | 0.05±0.01 |

| EW50T | Twill weave | |||||||

| EW80P | Plain weave | 80±2 | 30 | 30 | 34 | 34 | 3300 | 0.07±0.01 |

| EW80T | Twill weave | |||||||

| EW100P | Plain weave | 100±3 | 42 | 32 | 34 | 34 | 3300 | 0.09±0.01 |

| EW100T | Twill weave | |||||||

| EW130P | Plain weave | 130±3 | 25 | 23 | 68 | 68 | 3300 | 0.11±0.02 |

| EW130T | Twill weave | |||||||

| EW160P | Plain weave | 160±4 | 30 | 30 | 34 | 34 | 3300 | 0.14±0.02 |

| EW160T | Twill weave | |||||||

| EW200P | Plain weave | 200±5 | 42 | 32 | 38 | 38 | 3300 | 0.18±0.03 |

| EW200T | Twill weave | |||||||

| EW200P | Plain weave | 200±5 | 25 | 25 | 100 | 100 | 3300 | 0.18±0.03 |

| EW200T | Twill weave | |||||||

| EW200P | Plain weave | 200±5 | 20 | 17.5 | 136 | 136 | 3300 | 0.18±0.03 |

| EW200T | Twill weave | |||||||

| EW300P | Plain weave | 300±6 | 20 | 17.5 | 200 | 200 | 3300 | 0.27±0.05 |

| EW300T | Twill weave | |||||||

| EW300S | Satin weave | 300±6 | 56 | 54 | 68 | 68 | 3300 | 0.27±0.05 |

| EW400P | Plain weave | 400±32 | 20 | 17.5 | 268 | 268 | 3300 | 0.36±0.07 |

| EW400T | Twill weave | |||||||

For photovoltaics industry

For aerospace

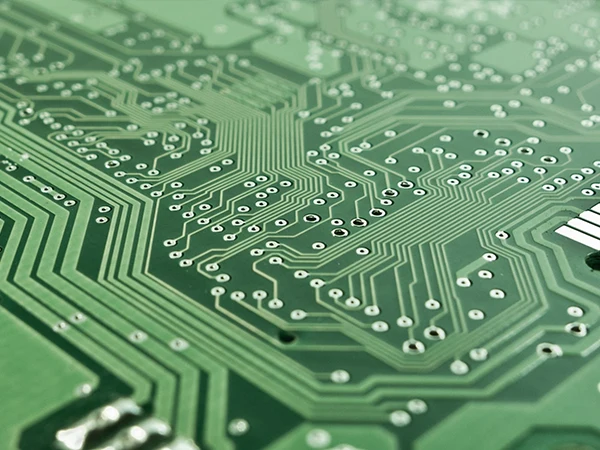

For electronics

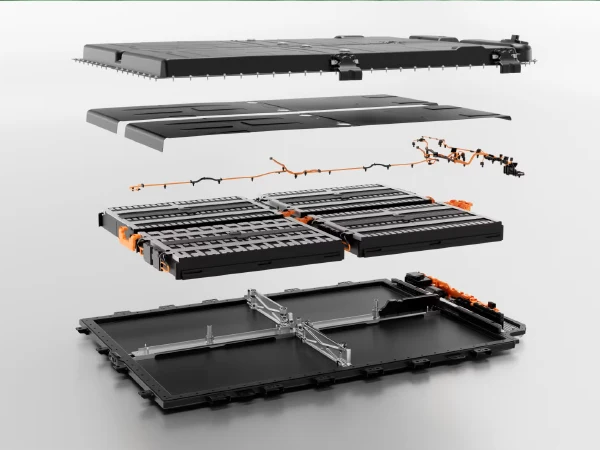

For new energy battery casings